The Evolution of CNC Technology: From Basics to Advanced Features

Have you ever wondered how modern manufacturing achieves such precision and efficiency? The answer lies in CNC technology, a field that’s undergone remarkable changes since its inception.

As we dive into the evolution of CNC technology, we’ll explore how these advancements have shaped the manufacturing landscape. Learn how it enhances the capabilities and productivity of various industries. Keep on reading to learn more!

Understanding the Basics of CNC Technology

CNC, or Computer Numerical Control, changed the way machining and manufacturing work. Before it was invented, machines had to be controlled by hand, which wasn’t as accurate or efficient. The first CNC machines were created in the 1950s, and they made a big difference in how things were made.

CNC machines are automated, meaning they can run by themselves with little help from humans. This helps make parts more accurate and consistent every time. With CNC, manufacturers can now make complicated parts much more easily. This has been very important in fields like aerospace, automotive, and healthcare, where precision is key.

How CNC Technology Has Evolved

The journey of CNC technology has been marked by continuous enhancement. Initially, CNC systems relied on paper tape for programming, which was tedious and time-consuming. Fast forward to today, and we have advanced software. There are digital interfaces that enable real-time monitoring and editing.

The following are key milestones in the evolution of CNC technology:

Digital Programming

Early CNC machines used G-code, a simple programming language. Now, more intuitive software can simulate machining processes before executing them.

Increased Speed and Efficiency

Today’s CNC machines operate at much higher speeds compared to their predecessors. This is thanks to advancements in motor technology and materials.

Integration of Automation

The incorporation of robotics has enabled unattended operations. This allows manufacturers to keep production lines running efficiently.

Advanced Materials

CNC technology has progressed to accommodate a wider range of materials like metals and composites. This increases applicability across various sectors.

3D Printing Integration

The rise of additive manufacturing has created opportunities for CNC technology to work alongside 3D printing. This enhances prototyping and production capabilities.

The Future of CNC Technology

The future of CNC technology is looking bright, with even more automation and smart features coming. As Industry 4.0 grows, CNC machines will be able to predict when they need maintenance, reducing unexpected breakdowns. Machine learning will help machines learn from experience, improving their performance over time.

New technology like artificial intelligence will make CNC systems even smarter. These systems will automatically adjust their settings while working to make sure the machining process stays accurate and efficient.

As competition in manufacturing gets tougher, companies will need speed, precision, and efficiency to stay ahead. Those who use the latest CNC technology will likely gain a big advantage. If you’re interested to learn more, check out this CNC machine shop for more insights.

Embracing the CNC Revolution

For manufacturers who want to stay competitive, investing in modern CNC technology is important. Understanding how CNC has changed over time helps you use it to its full potential. As the industry grows, knowing what new CNC machines can do helps you make better decisions for your business.

- GMT

- OTL

- ICL

- GMF

- FYE

- DTN

- UWU

- TT

- CFS

- BD

- NTM

- WUT

- MIL

- TMRW

- BG

- FWU

- TTYL

- WYFD

- WSG

- ETA Meaning

- AFK Meaning

- BRB

- OP

- Buff

- LMS

- ATP

- WTV

- ML

- IGH Meaning

- IMS

- LYK

- PTSO Meaning

- LTR

- NS

- Grool Meaning

- TMB

- PNP

- EDTWT

- WYLL

- CM Meaning

- Passenger Princess Meaning

- RQ Meaning

- BFFR Meaning

- NTY Meaning

- DTM Meaning

- LBVS Meaning

- FRL Meaning

- OTW

- WTW

- IMBO

- LCOL Meaning

- VHCOL Meaning

- Face Card Never Declines

- 4L Meaning

- Pink Person Meaning

- Blue Person Meaning

- Green Person Meaning

- FYM Meaning

- GL Meaning

- HCOL Meaning

- A Guide to Internet Slang for Jokes and Playful Teasing

- HU Meaning in Text

- CBFW Meaning

- Mullet

- Da Fuq Meaning

- WTF Meaning

- What Is Glazing Slang

- MCOL Meaning

- YWA Meaning

- FWM Meaning in Text

- What Does QQIA Stand For

- What Does LGBTI Stands For

- What Does GSD Stands For

- What Does LGBT2Q Stands For

- What Is Yaoi and BL

- Josou Seme

- Juevos

- Paizuri Meaning

- Corruption Kink

- Cockwarming Meaning

- Torpedophile

- Fap Chat

- Wassach

- Cockhair

- BUHB

- IDTS Meaning in Text

- Kest Gak

- r Bonersinpublic

- Pararam Tram

- TTM and TWM

- BBL

- Wanktube

- Time Stophentai

- Gripster

- HBY Meaning in Text

- Shook Meaning

- GG Meaning

- GOAT Meaning

- Bussin Meaning

- MBN

- FMTY Meaning

- AMOS

- What Is Rule 34

- Amongus R34

- Whats Up Chicken Butt

- Fangdangler

- Exposed Faggot and Exposed Fags

- TN Meaning

- HY

- Sneaky Links

- Memable

- What Does PMO Mean in Text

- How Accurate Are Love Calculators

- History of Love Calculators

- Love Calculators vs Astrology

- What Does LGBTQCIA Stand For

- TS

- HBU

- OOC Meaning

- Soft Launch

- Sneak Peeks

- Seggs

- Kenough

- IYKYK

- Facial Recognition in the Crypto Apps

- SFW

- What Is Broheim

- Synthetic Identity Fraud

- How to Choose the Right Insurance A Detailed Guide

- How to Choose the Right Doctor

- Essential Services Needed When Building or Repairing a House

- Slangs Terms in the Fashion Industry

- Kokushibo R34

- Intravert Meaning

- KGFE

- Rock God

- TW Meaning

- IKTR Meaning

- ILYK Meaning

- Oomfie Meaning

- What Does ND Meaning in Text

- What Does WAP Stand For

- B G Meaning

- ASF

- Allat Meaning

- Country Humans R34

- Widepeepohappy

- ODAAT Meaning

- Skyrocket Your Career Skills Refined by a Brisbane Business Coach

- R34 Toy Chica

- Upgrade Backyard with Smart Building Strategies

- Best Practices for Using Storage Tanks

- Product Liability Laws

- Nail Health Matters Effective Solutions for Managing Fungal Infections

- Outta Pocket Meaning

- Home Office Space

- Essential Techniques for Product Transport

- PU Meaning in Text

- What Is r Traps or Traps

- W R T Meaning

- How Technology Has Changed Business

- Adding Dedicated Web Hosting to Your Hosting as a Partner

- GGS Meaning

- Digital Marketing is Influencing Crypto Industry

- TradeFolder Review

- Your Ultimate Guide to Party Planning A Comprehensive Checklist

- SMTH Meaning

- Maximizing Your Returns The Importance of Strategic Tax Planning

- From Slang to Slots

- JP

- FN Meaning

- Skullet

- How to Obtain a Medical Prescription to Purchase a Disposable THC Vape

- Sprinkle Sprinkle Meaning

- The Essential GTM Guide Strategies for Success from Product Marketing Experts

- Are Yacht Rentals Worth the Investment for Corporate Retreats

- 4 Must Know Insights for Every Entry Level Developer on API Testing

- Fruity Fragrance of Pineapple

- The Ultimate Guide to Apartments for Seniors Finding Your Ideal Home

- Dog in Him

- I Got That Dog in Me

- Financial Mastery with the Investment Handbook

- XX Meaning in Text

- Unlock Homeownership with a Free ITIN Loan Quote Fast Efficient and Designed for You

- XD

- How to Edit a JPEG Like a Pro Step by Step Tutorial

- Meaning of TG

- WYMM Meaning in Text

- Caught in 4K

- SOS Meaning

- Productive Day

- Tweakin Meaning

- Unveiling the Power of IRA Investing

- What to Look for in a Law Firm SEO Expert

- CTFU

- Boba Tea Near Me Tips to Find Nearby Bubble Tea Spots

- S U Meaning

- What Does ISO Mean on Social Media and Texting

- H T

- The Crucial Role of Financing in Real Estate Development

- AWL Meaning in Text

- Live Webinar ClickMeeting Promoting Your Webinar Effectively

- Pawns App Is It a Legitimate Website for Online Surveys

- What Does NTN Mean in Text

- Caribbean Yacht Charters

- Meaning of Dropping Dimes

- What Does Stimmy Check Mean

- Retail ERP Software

- Big Sized Disciple

- The Role of Forensic Accountants in High Net Worth Divorces in Florida

- The Importance of Hiring an Estate Planning Attorney

- Brand Promotions

- Mar1uhh

- What Does WBU Mean

- Basic Arabic Slang for Talking with Arabs

- Gamers Slang

- What Is PVC Welding

- All About Printing Equipments

- The Contribution of Technology to the Growth of Situs Toto Platforms

- 5 Factors to Consider When Selecting an Investigative Agency to Handle Your Fraud Case

- How to Choose the Perfect Perfume Oil for Every Occasion

- Goated with the Sauce

- Chromer

- What Is Pager

- DiamondWhale Review

- Top 10 Business Ideas to Consider in European Countries

- Disposal Services Small Businesses

- Camwhor Meaning

- Noble Steed

- Smoke and a Pancake

- Comf

- How Robotics and Automation Are Revolutionizing Supply Chain Management

- TheJavaSea Me Leaks AIO TLP

- Biguns Meaning

- How to Gather Google Reviews for a Senior Citizen Center

- Why Choose an Online IOP for Your Mental Health Needs

- Jordan Shoes

- What Is Frave

- Necktie Design

- Email Campaign Management

- Long Term Pest Control

- How Can Businesses Best Leverage Artificial Intelligence

- 6 AI Influenced Business Trends Everyone Must Anticipate in 2025

- PAWG Meaning

- 5 Ways Financing to Plan the Wedding of Your Dreams

- Use a White Neon Sign for a Clean and Chic Look

- The Benefits of Cloud Faxing for Modern Businesses

- BBW Meaning

- GYAT

- Top Graphic Design Firms

- No Diddy Meaning

- Helping High School Students Set Realistic Goals for the Future

- Building Connections with Online Gaming Communities

- What Does Goon Caption Means

- Secrets That Your Blackjack Dealer Doesn't Want You to Know

- Insurance BPO

- What Is Incestables

- Online Visibility

- What Is Lumpty

- Sloppy Looking Means

- Young Couples

- Hafa Adai Meaning

- 448 Angel Number

- Maximize Performance on a Budget Friendly Hosting Plan

- 5 Casino Software Developers the United Kingdom is Known For

- Tuggie

- Snuffies

- Electric Bike

- Botulax 100 Units Achieving Optimal Results with Botulinum Toxin

- Class Action Attorneys

- YOLO

- ONG

- TBH

- WFA

- Lifestyle Adjustments That Can Improve Your Vision Health

- Easy Tips to Choose the Best Online Slot for Your Play Style

- The Psychology Behind Winning at Casino Games

- How Recent Tech Advancements Might Affect the Future of Crypto

- Finished Slangily

- What Does NFS Mean on IG

- What Types of Slang Are There in Different Types of Online Games

- FPPD Meaning

- HDBD Meaning

- Gaming The Ultimate Stress Busting Hobby

- Why Jiu Jitsu is a Proven Martial Art for Effective Self Defense Preparedness

- Commercial Warehouse for Rent

- Why Casino Gaming Sites Are a Favorite for Everyone

- Instagram Story Viewer for Privacy Conscious Users to View IG Profiles

- Earring Trends Whats Hot Right Now in 2024

- CNAT Meaning

- Is Digital Marketing a Bubble or a Stable Business

- WYF Meaning

- Boston Car Service for Executive Transfers to Meetings and Events

- Arrive in Style for Your Prom Night with Car Service San Diego

- Limo Service San Diego Helps You Impress at Business Meetings

- Black Limo Service Seattle for Tips for Wedding Transportation

- The Best Features of Limo Service Connecticut for Wedding Transport

- Key Property Details Explained by Home Inspectors Fort Myers

- Moose Knuckle Meaning

- Urban Clothing Apparel

- GITSS Meaning

- Whats the Right Addiction Treatment for You Find Out Now

- Common Scientific Calculator Mistakes Avoid These Pitfalls

- The Benefits of Evaporative Cooling Energy Efficiency and Cost Savings

- How to Style Your Netball Shorts for Both Practice and Casual Wear

- Understanding the Property Market Trends and Forecasts

- Alternative Investments in Australia Options Beyond Traditional Assets

- Key Considerations When Choosing a Commercial Buyers Agent

- Casualness Delight

- How Do Football Clubs Manage Star Players

- YK Meaning

- KEKL Meaning

- What to Look for in an Everyday Bra

- How to Raise Your Online Lottery Probabilities of Winning

- Every Door Direct Mail

- What Is Spankbang

- NOTAFLOF Meaning

- Energy Optimization

- Edibles Online

- OTD Meaning

- Botox in Jaw for TMJ

- Buying a Sea View Villa in Dubai for Investment

- DK Meaning

- Professional Documents

- What Does PSE Mean

- CLB Meaning

- Mayan Tomb Uncover Hidden Treasures in the Heart of the Jungle

- SEO Agency in Dubai

- Top 10 Amenities to Look for in Budget Motels

- GTK Meaning

- Liability Lawyers

- What Does Blud Mean

- Partition Actions

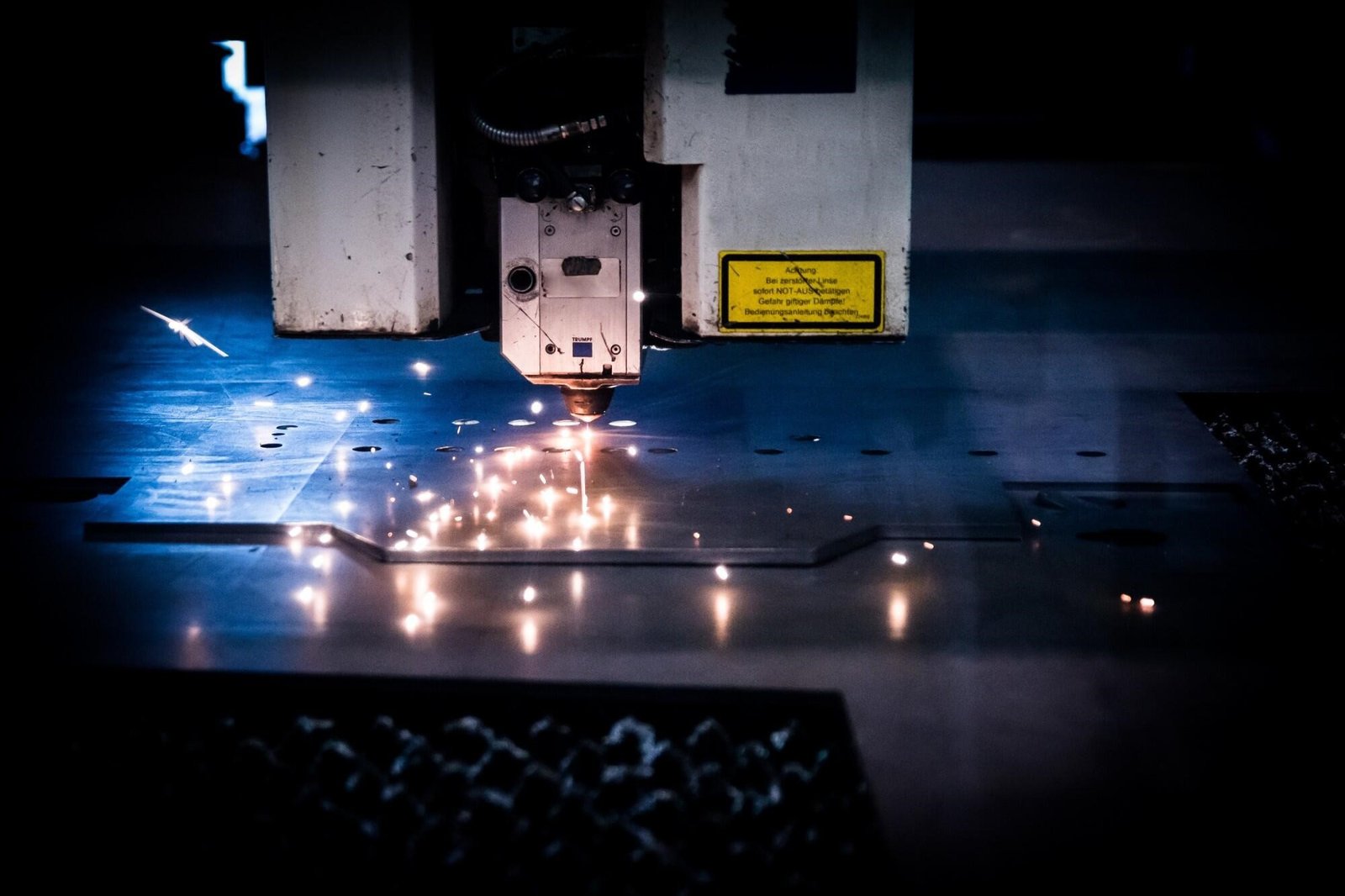

- Laser Cutting Steel

- Charcuterie Board Catering

- Western Boots

- Affordable Self Storage

- What Does Hmph Mean

- What Does Feeling Froggy Mean

- How Can Digital Marketing Services Help You Find a Kratom Shop in Phoenix

- How to Manage Pre Exam Nerves for the DAT

- Camcrush Meaning

- Download TikTok and Twitter Videos with SSSTik

- Financial Steps to Follow When Relocating from Germany

- Popular Entertainment Franchises for Launching a Successful Business

- What Does So Retro Mean

- Cycling Certification

- Crotch Rope

- Why Debt Funds Are Essential for Risk Management

- Goose Decoy

- Psychology Behind Humans Adoring Superheroes

- What Does Art of Zoo Mean

- Meaning of SMIRF

- 5 Ways Bed Pads Can Improve Comfort for Adults

- How to Sign a Proposal Online

- Old Mother

- Car Crash Attorneys

- Dental Advertisement

- Advanced Baccarat Player Betting Strategies to Get High Returns

- What Does A Band Money Mean

- How Do Apparel Fulfilment Services Integrate with E Commerce Platforms A Comprehensive Guide

- Optimizing Daily Workflows with Online Task Management Solutions

- LOML Meaning

- OIY Meaning

- SP Meaning in Text

- Exploring the Allure of Popular Themed Online Slot Games

- Cheap Loan with Low Interest Rates

- The Role of AI in Healthcare ChatGPTs Potential Within HIPAA Guidelines

- Shilajit in the UK Discover the Benefits of This Ancient Superfood

- How Payout Percentages Influence Online Slot Jackpot Wins

- Simplify Your International Journey How to Get an Apostille Effectively

- Funcle Meaning

- Xiao R34

- A Beginners Guide to Online Shopping Safe Payment Practices

- Best Pistols

- Deck Boots

- The Use of BiPAP and VPAP in the Treatment of Sleep Apnea What Are the Advantages of Modern Technologies

- How to Choose the Right Kurkuma for Your Needs

- WDYLL Meaning

- Top Ways to Unwind and Relax Online After a Busy Day

- How to Discuss Your Hepatitis C Treatment Plan with Your Doctor

- Wrongful Dismissal Lawyer

- Car Accident Lawsuit Process

- Working Capital Fund

- Small Apartment Complex

- Ideas for Fitness

- Studio House

- Duplex High Rise Apartment

- Apartment Gym Workout

- 4 Bedroom Apartment

- What Does YNS Mean in Slang

- What Does Chupapi Munyayo Mean

- Three Bedroom

- Study Areas

- 7 Ways to Look for Top Quality Kratom Drinks During Cyber Monday Offers

- What Does Fujitsu Mid Tier SEER Rating Mean

- What Does Ground Time Mean

- Bone Graft Material

- Liquid Cooled Generator

- How Can You Maximize Compensation After a Car Accident in Queens Expert Tips and Strategies

- Why Invest in Maid Services for a Cleaner Healthier Home Environment

- What Does Meaning With Trailer Mean With Perm

- What Is a Casino VIP and How Do You Become One

- Unraveling Esports Betting From Its Evolution to Winning Tips

- What Does NAKT Mean

- What Does Nice Try Diddy Mean on Instagram

- Gated Community Homes for Rent

- What Does OV Hoe Mean

- How Herbal Remedies Are Making Their Way Into Smoothies and Teas

- How to Unlock Savings with Canada Kratom Express Coupons

- Mini Excavator in Australia

- 7 Diet Additions You Should Invest in Today

- What Features Matter Most in a Small TV

- Telehealth GPS Explained What to Expect From Online Doctor Visits

- Applied Health Science Degree in Dermal Therapy

- What Does Previewing on the Seestar S50 Mean

- What Does SPWM Mean in Text

- How Art Elevated Online Slots

- What Does The Mans Scope Mean

- What Does The Name Xyonna Mean

- Professional Insurance Services

- What Is The Meaning of Gantos Axe

- What Does 69 Ms Mean for Latency

- How Can Businesses Optimize Costs With Mobile Solutions in Jamaica

- Seasoning Blend

- Meaning of FKH

- GTS Meaning

- What Does Hmmm Mean From a Guy Flirty

- Best Ways to Keep Your Hair Healthy and Shiny Expert Tips and Tricks

- What Does Samba Mean in Tshiluba English

- What Does IMK Mean in Texting

- Boob Job Recovery

- Dream Living Room

- Motorcycle Accident

- What Does GGE Mean Slang

- NFS Mean on Wizz

- Payment Processed

- How Slot Games Are Made Learn About Game Development

- What Does Dac Biet Mean

- Comprehensive Pearland Plumbing Services for Your Home and Business